Engineering

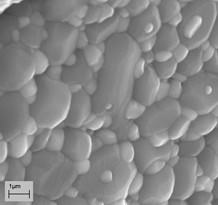

At Kläger, we dedicate a great deal of time and energy to the question of materials. The chosen material

must deliver genuine added value to the application, and only then does it form a basis for successful implementation.

We develop new recipes associated with mixed oxide ceramics and we migrate these new materials into injection molding technology. This vast compendium of knowledge about materials is what our customers encounter when we advise them on their choice of materials.

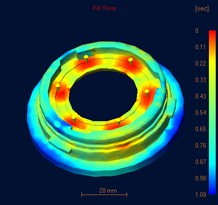

In the course of ‘real’ product development, we once again leverage the synergetic skills sets of our various departments. In close consultation with the customer, and with our project engineer assuming overall responsibility, we assemble a team of specialists that then maps out the development concept, affording due consideration to all functional, economic and technical specifications.

The first step involves digital implementation of the component to create a design suitable for injection molding in an appropriate material, and then to extrapolate a 3D model. These data are produced on Pro-Engineer and guide us through the entire production process. They serve as a basis for the tool concept, tool design and also for the erosion and milling programs (CAD / CAM).